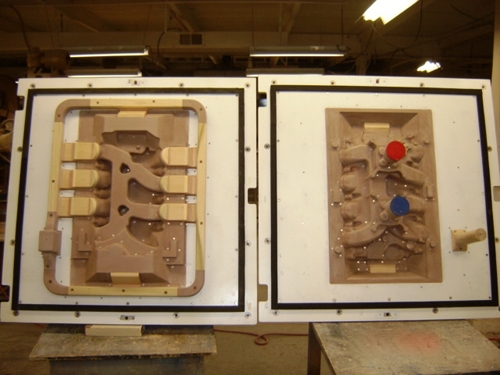

A v-process aluminum foundry recently contracted Woodward Industries, Inc. to produce a series of v-process cope and drag patterns. We manufactured these patterns based on customer supplied CAD design files. Using our CNC machining centers, Woodward Industries, Inc. was able to successfully manufacture this series of v-process patterns, meeting our client’s unique product requirements.

Meeting a .001 of an inch precision tolerance, we manufactured all patterns using RenShape 460 polyurethane material. Each pattern was mounted on boards for a 36×36 inch flask, and then was sanded, sealed, and waxed, which provided these patterns with a smooth, durable finish. Using a #72 drill bit, we produced all required screen and drill vents, and each pattern contained one impression. All mounts, vents, and gates were additionally constructed to meet our customer’s unique specifications.

Having years of expertise in the mold making business, we produced these patterns with a 1.01 shrinkage allowance, ensuring that after the parts are cooled, they would still meet our client’s precise dimensional specifications. Combining a great deal of industry experience in vacuum molding technology, Woodward Industries, Inc. was able to successfully manufacture a series of V-process patterns for the aluminum foundry industry.